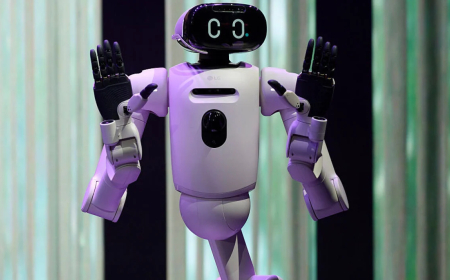

Toyota contracts seven Agility humanoid robots for Canadian factory

Toyota has contracted seven Agility humanoid robots for deployment at its Canadian factory, marking a significant step toward automating logistics and material-handling operations.

After a year-long pilot project, Toyota’s Canadian manufacturing subsidiary has contracted seven humanoid robots to operate inside a plant that builds RAV4 SUVs, using a robots-as-a-service agreement.

“After evaluating several robots, we are excited to deploy Digit to improve the team member experience and further increase operational efficiency in our manufacturing facilities,” Toyota Motor Manufacturing Canada (TMMC) President Tim Hollander said in a statement.

Agility Robotics produces the Digit robot, a company spun out of Oregon State University in 2015. Digit is designed for industrial settings where it can operate without human supervision, often moving items between two automated production lines. In this deployment, the robots will unload totes of auto parts from an automated warehouse tugger.

While having seven robots handle physical, repetitive work may sound modest compared with flashy videos of humanoids doing acrobatics, the real-world deployment of humanoid robots in active workplaces remains uncommon and challenging. Showing a capability in a lab environment is one thing, but integrating robots into a company’s existing workflow — including upkeep, charging, maintenance schedules, and reliability expectations — is far more complex.

“When the tech companies spend real time in the field understanding the task that needs to be operated, the real workflows that happen…that’s when we will see a huge uptick in adoption,” Ram Devarajulu, a VP at Cambridge Consultants, said at the Humanoids Summit in late 2025.

Agility is widely seen as one of the leaders in moving humanoid robots beyond the lab, with Digits already working in similar roles for logistics and industrial operators such as GXO, Schaeffler, and Amazon. The company also offers a proprietary cloud-based software platform, Arc, that allows customers to manage fleets of robots, and it argues that AI will play a major role in reducing deployment costs.

“Cost of deployment … can be more than the price of the robot by a lot,” Pras Velagapudi, Agility’s CTO, said in an interview last year. “AI tools let us decrease the cost of deployment, decrease the amount of time getting the robot configured and getting it operating at a level of performance that they want.”

TMMC and Agility said they will use the engagement to explore additional use cases that reduce repetitive physical workloads for human employees and shift them toward higher-value tasks.

Agility is also preparing a next-generation humanoid robot designed to be safe operating alongside human workers. Current humanoid robots that are strong enough to lift heavy loads are still generally considered too unreliable to operate autonomously around people.

Competitor Figure AI tested its Figure 02 robots in a BMW factory for 10 months last year, and the company said the robots unloaded 90,000 parts during that period. Other companies running humanoid pilot programs include Apptronic, Unitree, Tesla, Boston Dynamics, 1X Technology, and Reflex Robotics.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0