Freeform raises $67M Series B to scale up laser AI manufacturing

Freeform has raised $67 million in Series B funding to expand its AI-powered laser manufacturing platform, aiming to modernise industrial production with automation and precision fabrication.

Tech investors still haven’t let go of the idea that making physical products could someday move with the same speed and convenience as shipping software.

Executives at Freeform, the startup building a new kind of 3D-printing system for metal parts, told TechCrunch that the company has raised $67 million in Series B funding to scale its manufacturing platform.

The round drew participation from Apandion, AE Ventures, Founders Fund, Linse Capital, Nvidia’s NVentures, Threshold Ventures, and Two Sigma Ventures. Freeform did not share its post-money valuation, though PitchBook lists it at $179 million.

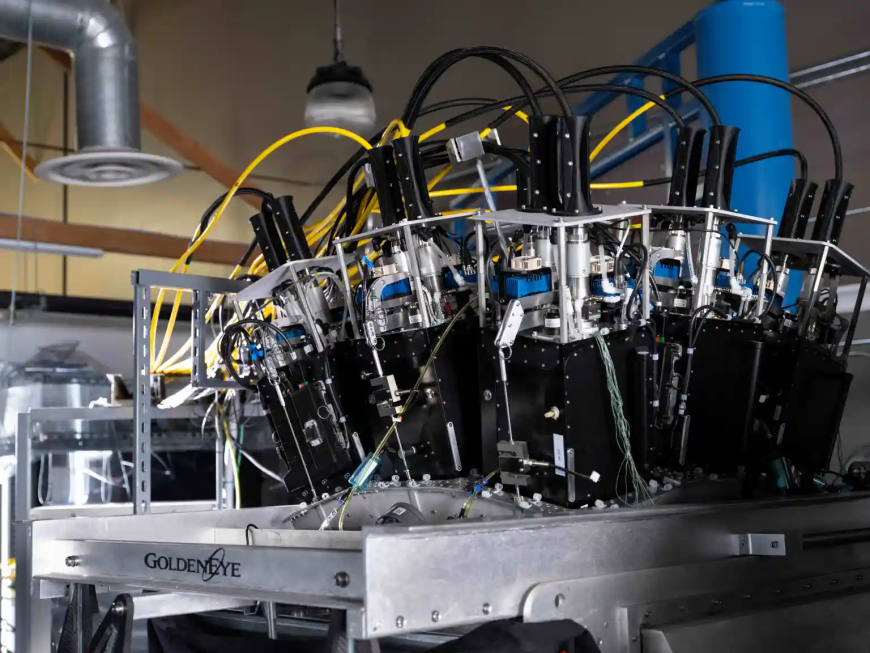

CEO and co-founder Erik Palitsch said the new capital will be used to upgrade the company’s current GoldenEye printing system — which uses 18 lasers to fuse metal powders into high-precision components — into a next-generation version. The upcoming platform, called Skyfall, is expected to use hundreds of lasers and produce thousands of kilograms of metal parts per day.

The effort represents the latest step in a vision Palitsch launched in 2018, after working on rocket engines at SpaceX, where he said the team learned that industrial metal-printing machines are costly, fragile, and not built for mass manufacturing.

Palitsch said Freeform’s goal was to design the platform from the ground up for higher throughput and flexibility, with a heavy focus on active software controls. He described the system as “AI native,” pointing to the company’s partnership with Nvidia that gives it access to advanced GPUs.

“I think we’re the only quote-unquote manufacturing company out there that has H200 clusters in a data centre on site,” Palitsch told TechCrunch. “What are they doing? We’re running real-time physics-based simulations and learning all the different aspects of the end-to-end manufacturing workflow.”

Freeform says the sensor data gathered across its manufacturing platform — along with information produced during simulations — helps the company rapidly improve both the quality and quantity of its output.

“We have more meaningful data on the physics of the metal-printing process than any company in the world,” said Cameron Kay, the company’s head of talent.

While Palitsch declined to name any customers, he said Freeform is already shipping hundreds of “mission-critical” parts to buyers each week. The company now plans to add as many as 100 new employees and expand its facility to begin fulfilling its contract backlog.

The broader manufacturing-as-a-service category has been gaining momentum as investors show growing interest in companies building vehicles, robots, and energy systems. Hadrian, for example, has reached a reported valuation of $1.6 billion while developing automated defence production, and both VulcanForms and Divergent have raised hundreds of millions of dollars to build their own metal-printing services.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0